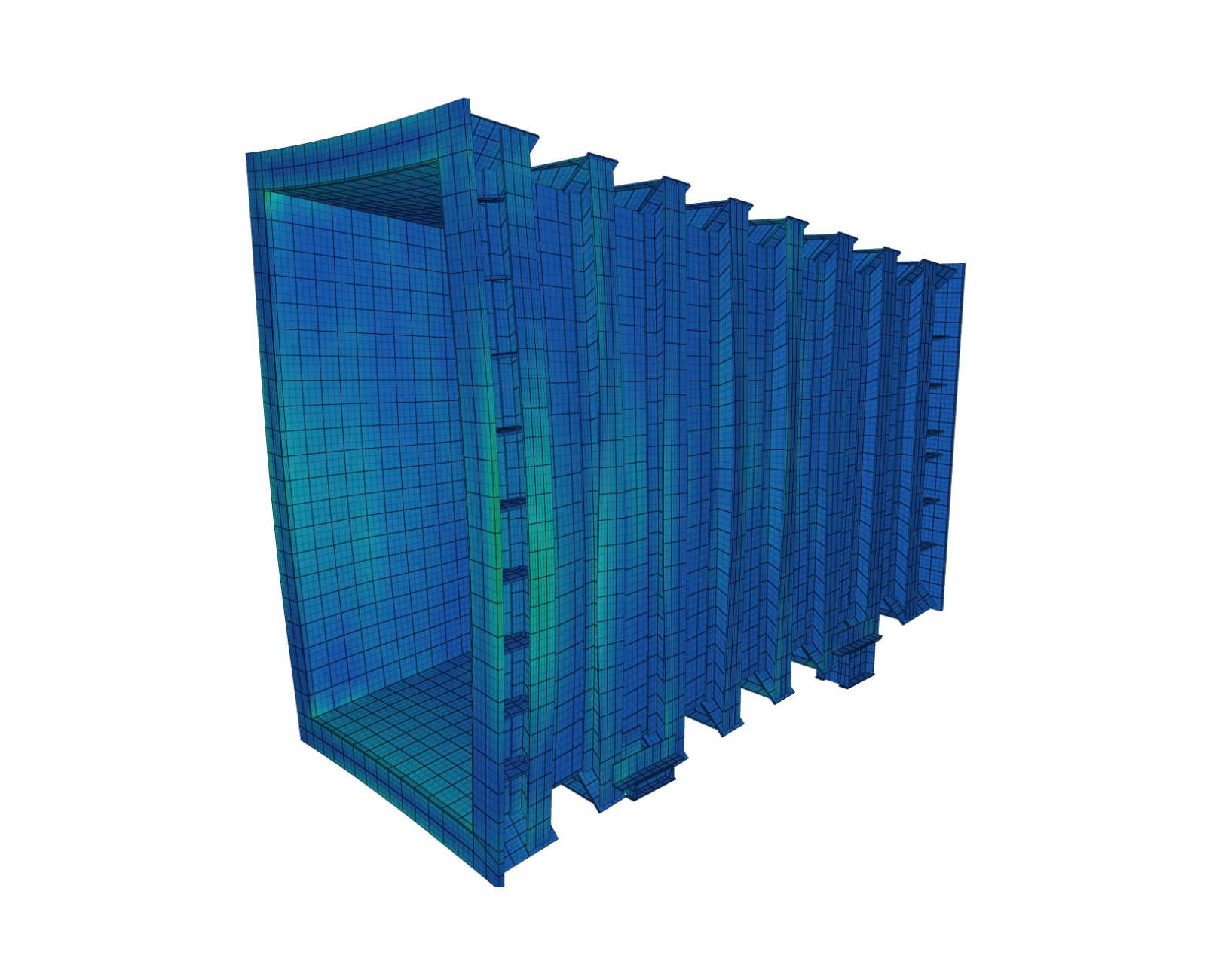

Reference projects

Who are we?

Enodo was founded in 2018, and is a spin-off company from the Structural Impact Laboratory (SIMLab) at the Norwegian University of Science and Technology. We specialize in finite element simulations with a focus on material non-linearity. Currently we are 5 employees, located in Drammen and Trondheim, Norway.

Jens Kristian Holmen, PhD

CEO

jens@enodo.no

Joakim Johnsen, PhD

CTO, Associate Professor

joakim@enodo.no

Henrik Granum, PhD

Senior Engineer

henrik@enodo.no

Johan Kolstø Sønstabø, PhD

Principal Engineer

johan@enodo.no

Lars Marcus Løken, MSc

Senior Engineer

marcus@enodo.no

Our services

-

FE SIMULATION CONSULTANCY

We are experts in non-linear finite element simulations.

-

EXPERIMENTAL TESTS

Through our collaboration with NTNU, we can offer everything from material characterization to full-scale component testing under both static and dynamic loading.

-

PARAMETER IDENTIFICATION

We have vast experience in parameter identification for material models for a wide range of materials: metals, concrete, polymers and wood.

-

SUPPORT

We can offer general support with FE simulations, product development and structural engineering.